PVC Stabilizers

PVC Stabilizers Specification

- Smell

- Neutral

- Molecular Formula

- Varies by formulation

- Molecular Weight

- Varies by formulation

- HS Code

- 38123090 (indicative may vary by country)

- Solubility

- Not soluble in water; soluble in organic solvents

- EINECS No

- Variable; depends on the stabilizer type

- Grade

- Industrial grade

- Physical Form

- Powder or liquid depending on the type

- Melting Point

- Not applicable (varies depending on the formulation)

- Ingredients

- May include metallic soaps organotin compounds or mixed metal stabilizers such as Ca-Zn or Ba-Zn

- Taste

- Odorless

- Structural Formula

- Dependent on the specific stabilizer compound (e.g. organotin lead calcium-zinc types)

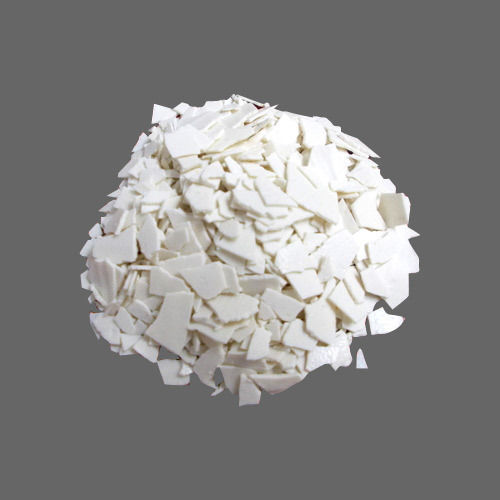

- Shape

- Granular/powder or liquid form

- Density

- 2.2 Gram per cubic centimeter(g/cm3)

- Shelf Life

- Typically 12-24 months if stored under recommended conditions

- Storage

- Store in a cool dry place away from moisture and direct sunlight

- Usage

- Primarily in rigid and flexible PVC manufacturing for pipes profiles cables and films

- Poisonous

- NO

- Ph Level

- Neutral to slightly alkaline (specific to composition)

- Appearance

- White powder or clear liquid

- Purity

- Varies by formulation

- Application

- Used to stabilize polyvinyl chloride (PVC) against heat and UV degradation

- CAS No

- Varies based on the type of stabilizers used (e.g. calcium stearate - CAS 1592-23-0)

- Properties

- Heat stability UV protection enhances processing improved weather resistance

About PVC Stabilizers

stabilisers for PVC compounds are characterised by a central tin atom, surrounded by alkyl and acidic groups. Mixtures of mono and dialkyl tin salts are used and commercial tin heat stabilisers typically vary the ratio, depending on the performance and property requirements of the final product.

Advanced Protection for PVC Products

PVC stabilizers are engineered to safeguard PVC products from the detrimental effects of heat and UV exposure, extending their durability and lifespan. With a choice of powder or liquid forms, these additives seamlessly integrate into manufacturing processes and enhance the physical and weather-resistant properties of end products. Their compatibility with a wide array of industrial uses ensures versatile and effective PVC stabilization for diverse applications.

Optimal Use and Handling Recommendations

Store PVC stabilizers in a cool, dry place away from direct sunlight and moisture to prevent degradation. Ensure the containers are tightly sealed and check purity and grade before use. Adhering to these guidelines, users can maximize the shelf life (up to 24 months) and maintain product performance for consistently reliable manufacturing outcomes.

FAQs of PVC Stabilizers:

Q: How do PVC stabilizers protect polyvinyl chloride products?

A: PVC stabilizers inhibit heat and UV-induced degradation of PVC by neutralizing hydrochloric acid formed during processing and exposure. This action helps preserve physical integrity, color, and flexibility, extending the functional lifespan of PVC-based products.Q: What are the main benefits of using PVC stabilizers in manufacturing?

A: Key advantages include improved heat stability, enhanced UV resistance, better processing properties, and superior weather resistance. These benefits result in longer-lasting PVC items, reduced yellowing, and minimized brittleness over time.Q: When should PVC stabilizers be added during PVC processing?

A: PVC stabilizers are typically blended with PVC resin and other additives before the extrusion or molding process. Adding them at the initial mixing stage ensures thorough dispersion and optimum protection throughout the product lifecycle.Q: Where are PVC stabilizers most commonly used?

A: They are widely utilized in manufacturing both rigid and flexible PVC products, such as pipes, window profiles, cables, films, and sheets. Their use is prevalent in industrial applications requiring durable, weather-resistant, and UV-stable PVC materials.Q: What storage conditions are recommended for PVC stabilizers?

A: For best results, store PVC stabilizers in a cool, dry location, shielded from direct sunlight and moisture. Proper storage safeguards against clumping, degradation, and loss of effectiveness, supporting optimal shelf life of 12-24 months.Q: How can I determine the right type of PVC stabilizer for my application?

A: Selection depends on application requirements, processing conditions, and regulatory considerations. Organotin, calcium-zinc, and mixed metal stabilizers each offer specific performance characteristics. Consulting with a supplier can help match the stabilizers properties to your products needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in acids Category

Epoxidized Soybean Oil

Application : Plasticizer and stabilizer for PVC coatings adhesives and sealing materials, Other

Usage : Enhances flexibility durability and thermal stability in plastic products

Storage : Other, Store in a cool dry place; avoid direct sunlight

Refractive Rate : 1.4711.475

Physical Form : Liquid

Melting Point : Not applicable for oils; typically in liquid form at room temperature

Nylon 66

Application : Other , Used in the production of fibers for textiles and carpets engineering plastics and reinforcement materials.

Usage : Primarily utilized in industrial manufacturing processes to create durable and lightweight materials.

Storage : Other, Store in a cool dry place away from direct sunlight and moisture.

Refractive Rate : 1.53

Physical Form : Solid

Melting Point : 255C

PVC Paste

Application : Used in coatings flooring wall coverings adhesives and plastics manufacturing, Other

Usage : Primarily used to produce flexible and rigid PVC products through pastebased processes

Storage : Other, Store in a cool dry place away from direct sunlight and moisture

Refractive Rate : 1.5441.550

Physical Form : Other, Fine white powder or paste

Melting Point : Softens at approximately 80C; degrades at 140160C

Calcium Carbonate Filler Masterbatch

Application : Other , Used in plastic manufacturing especially as a filler in polyethylene and polypropylene products

Usage : Enhances mechanical properties reduces production costs and improves appearance of plastic products

Storage : Other, Store in a cool dry and wellventilated place away from moisture

Refractive Rate : 1.59

Physical Form : Other, Granules or pellets

Melting Point : 825C (decomposes)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS