Polyurethane Raw Materials

Polyurethane Raw Materials Specification

- Ingredients

- Typically contains polyols isocyanates additives and catalysts

- CAS No

- Varies based on specific compound (e.g. 101-68-8 for MDI or 584-84-9 for TDI)

- Refractive Rate

- 1.50 - 1.55 (typical for polyurethane-based materials)

- Purity

- Usually 99% dependent on the specific raw material

- Shape

- Liquid or granular (depending on form)

- Molecular Formula

- Variable (depends on specific polymer type)

- EINECS No

- Varies based on component (e.g. 202-966-0 for MDI 209-544-5 for TDI)

- Solubility

- Insoluble in water; soluble in organic solvents (e.g. acetone)

- Structural Formula

- Based on the reaction of diisocyanates and polyols (varies)

- Appearance

- Clear to slightly yellow liquid solid pellets or powder

- Smell

- Slightly characteristic

- Melting Point

- Varies by composition typically softens rather than melts

- Physical Form

- Liquid powder or solid (depends on the type of raw material)

- Taste

- Odorless or neutral

- Usage

- As a raw material for manufacturing polyurethanes in various industries (automotive construction furniture etc.)

- HS Code

- 3909.50.00

- Density

- 1.3 Gram per cubic centimeter(g/cm3)

- Poisonous

- NO

- Grade

- Industrial grade; specialty grades available

- Shelf Life

- Typically 12 months when stored properly

- Storage

- Store in a cool dry and well-ventilated place away from direct sunlight

- Properties

- High versatility excellent mechanical properties and strong chemical resistance

- Molecular Weight

- Varies by formulation

- Ph Level

- Neutral to slightly basic

- Application

- Used in making foams adhesives coatings elastomers and sealants

About Polyurethane Raw Materials

Our polyurethane additives include TEGOSTAB® silicone surfactants, KOSMOS® and TEGOAMIN® catalysts, TEGOCOLOR® color pastes, GORAPUR® release agents, and ORTEGOL® performance additives.Exceptional Versatility and Properties

Polyurethane raw materials are celebrated for their adaptability and robust mechanical properties. Their unique molecular structure, derived from the reaction of diisocyanates and polyols, offers strong chemical resistance and excellent performance in a variety of applications. Whether used to produce flexible foams, adhesives, coatings, or elastomers, these materials deliver consistent results across many industrial sectors.

Diverse Industrial Applications

From automotive interiors to furniture upholstery and construction sealants, polyurethane raw materials play a critical role in modern manufacturing. Available as powders, liquids, or solids, they can be formulated to meet specific product needsensuring ideal characteristics for foaming, bonding, surface protection, or flexibility.

FAQs of Polyurethane Raw Materials:

Q: How are polyurethane raw materials typically used in manufacturing?

A: Polyurethane raw materials serve as the essential ingredients for producing foams, coatings, sealants, adhesives, and elastomers. Manufacturers blend polyols, isocyanates, and additives according to the desired product specifications, allowing for customization in different industries such as automotive, construction, and furniture.Q: What is the recommended storage process for polyurethane raw materials?

A: To preserve quality and extend shelf life, polyurethane raw materials should be stored in cool, dry, and well-ventilated environments away from direct sunlight. Proper storage conditions typically allow a shelf life of around 12 months.Q: What are the benefits of using polyurethane raw materials in construction and automotive industries?

A: These materials offer excellent versatility, strong mechanical properties, and resistance to chemicals, making them ideal for applications like insulation, structural components, adhesives, and protective coatings. Their adaptability helps manufacturers meet specific performance and safety requirements.Q: When should specialty grades of polyurethane raw materials be selected?

A: Specialty grades are chosen when unique performance attributes are needed, such as enhanced flexibility, flame retardancy, or resistance to specific chemicals. These grades are especially valuable in sectors with demanding technical standards or regulatory requirements.Q: Where are polyurethane raw materials processed and distributed?

A: Raw polyurethane components are manufactured, distributed, and supplied globally, including by exporters, traders, and suppliers based in Germany. They are processed in dedicated chemical facilities to ensure quality and consistency before reaching manufacturers and end-users.Q: What is the molecular structure and composition of polyurethane raw materials?

A: Polyurethane raw materials typically contain polyols, isocyanates, various additives, and catalysts. The precise molecular formula varies with formulation, but it is always based on the reaction of diisocyanates and polyols, resulting in a flexible, yet durable polymer chain.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Speciality Chemicals Category

Hydroquinone

Shelf Life : 2 years under proper storage conditions

Poisonous : Other, Yes toxic if ingested inhaled or absorbed through the skin

Grade : Industrial grade Cosmetic grade

Storage : Store in a cool dry place away from light and incompatible substances, Other

Properties : Highly reactive with oxidizing agents reduces easily colorless or slightly colored crystals

Application : Used in photographic developers as an antioxidant for fats and oils and as an ingredient in skinlightening products, Other

Biocide Chemicals

Shelf Life : 2 years from the date of manufacture

Poisonous : YES

Grade : Industrial grade

Storage : Store in a cool dry and wellventilated area away from direct sunlight, Other

Properties : Antimicrobial fungicidal and bactericidal properties

Application : Water treatment preservation and disinfectants, Other

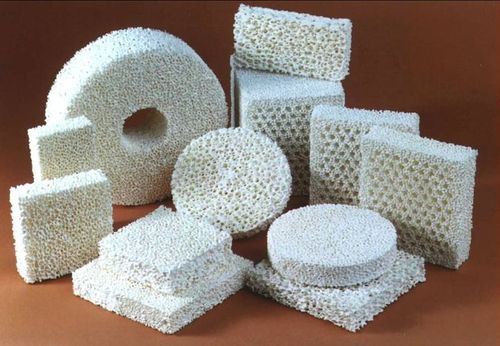

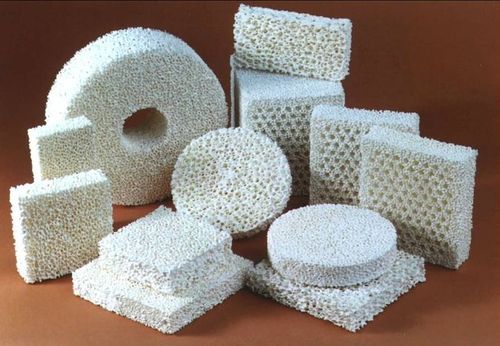

Rubber Chemicals

Shelf Life : 23 years under proper storage conditions

Poisonous : NO

Grade : Industrial Grade

Storage : Other, Stored in cool dry and ventilated environments away from direct sunlight

Properties : Improves tensile strength elasticity and heat stability of rubber

Application : Other , Used as vulcanization accelerators antioxidants or stabilizers in rubber manufacturing

Stannous Octoate

Shelf Life : 12 months in an unopened container when stored properly

Poisonous : YES

Grade : Industrial Grade

Storage : Other, Store in a cool dry and wellventilated area; avoid exposure to moisture and heat

Properties : Catalytic activity low volatility and efficient polymerization promoter

Application : Catalyst in polymerization especially for polyurethanes and silicones, Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS