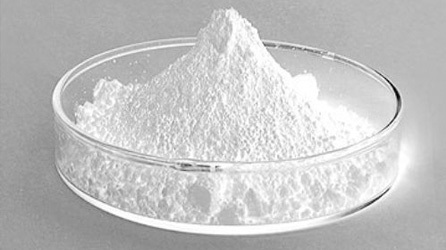

Ground Calcium Carbonate Powder

Ground Calcium Carbonate Powder Specification

- Usage & Applications

- Pigment, Filler, Extender and Coating agent in industrial processes

- Density

- 2.90 Gram per cubic centimeter(g/cm3)

- Purity(%)

- 98%

- Water Absorption

- Very Low

- Surface Finish

- Smooth and Uniform

- Hardness (%)

- Mohs Hardness: 3

- Chemical Composition

- CaCO3 (Calcium Carbonate)

- Form

- Powder

- Application

- Used in Paper, Paints, Plastics, Rubber, Construction, Ceramic Industries

- Melting Point

- 825C (Decomposes to CaO at 825C)

- Product Type

- Industrial Powder

- Types of Refractories

- Not applicable (Commonly used as filler, not as a refractory)

- Shape

- Fine Powdery Form

- Porosity

- Low Porosity

- Dimensional Stability

- Excellent dimensional stability

- Strength

- High mechanical strength for filler applications

- Specific Gravity

- 2.7 2.9

- Thermal Conductivity

- Low

- Color

- White

- Refractive Index

- 1.591.60

- Whiteness

- >96%

- Packing Size

- 25 kg, 50 kg, and jumbo bags

- Toxicity

- Non-toxic and safe for handling

- Moisture Content

- <0.3%

- pH Value

- 8.59.5 (in 10% slurry)

- Oil Absorption

- 1822 g/100g

- Insoluble Matter

- <1%

- Loss on Ignition (LOI)

- <44%

- Particle Size

- 550 microns (customizable as required)

About Ground Calcium Carbonate Powder

To deliver the best quality chemicals, we are engaged in manufacturing, exporting and supplying the finest quality Ground Calcium Carbonate Powder. The offered powder is finely processed at our sophisticated processing unit using superlative quality chemical compounds and modern processing techniques in sync with set market quality standards. This powder is used in construction industry either as a limestone aggregate or building materials. Apart from this, we are providing this Ground Calcium Carbonate Powder to the clients at highly competitive prices.

Features:

-

Accurate composition

-

Longer shelf life

-

Precisely processed

-

Unadulterated

Details:

Calcium Carbonate is a common substance found in rocks in all parts of the world and is the main component of shells of marine organisms,snails,coal balls,pearls and eggshells.The main use of Calcium Carbonate is in the construction industry either as a building material or limestone aggregate.

Calcium Carbonate is widely used medicinally as an inexpensive dietary calcium supplement or gastric acid.

Consistent Quality and Purity

Ground Calcium Carbonate Powder boasts a purity of 98% and is characterized by outstanding whiteness and low moisture, ensuring consistent results in all industrial applications. Its chemical stability, low oil absorption, and smooth texture make it suitable for sensitive and high-performance formulations.

Versatile Industrial Applications

This powder serves as a vital pigment, filler, extender, and coating agent across the paper, ceramics, paints, plastics, rubber, and construction industries. Its customizable particle size and excellent mechanical properties enhance product performance and cost-effectiveness for manufacturers.

Safe and Easy Handling

Non-toxic and safe for human contact, Ground Calcium Carbonate Powder is straightforward to manage during storage or use. Its stable nature, low water absorption, and low porosity further simplify handling, mixing, and integration into various production processes.

FAQs of Ground Calcium Carbonate Powder:

Q: How is Ground Calcium Carbonate Powder typically used in industrial applications?

A: This powder is primarily used as a pigment, filler, extender, and coating agent in industries such as paper, paints, plastics, rubber, ceramics, and construction. Its fine powder form and customizable particle size enhance surface finish, strength, and processing efficiency in products.Q: What benefits does Ground Calcium Carbonate Powder offer over other fillers?

A: Its high purity (98%), excellent whiteness (>96%), low moisture content, and non-toxic properties provide superior finish, reliability, and safety. Additionally, it improves mechanical strength and dimensional stability while maintaining low thermal conductivity and porosity.Q: Where can I purchase Ground Calcium Carbonate Powder and in what packaging sizes?

A: The product is available from distributors, exporters, importers, manufacturers, suppliers, and traders across India and internationally. Standard packing sizes include 25 kg, 50 kg, and jumbo bags, accommodating various industrial scale needs.Q: What makes this calcium carbonate powder safe and user-friendly?

A: With non-toxic properties, very low moisture, and low insoluble matter (<1%), this powder is safe for handling and does not pose toxicity risks. It is easy to store and incorporate into manufacturing processes without requiring special safety measures.Q: How does particle size customization benefit specific processes?

A: Customizable particle sizes (550 microns) allow for tailored performance in different applications, ensuring optimal dispersion, surface finish, and product strength. This enhances compatibility with process requirements in paper, paint, plastics, and other industries.Q: What is the typical process for integrating this product into manufacturing?

A: The powder is usually mixed into slurries, compounds, or resin systems depending on the industry application, benefitting from its high purity, low moisture, and stable properties for uniform blending and consistency throughout the end product.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Minerals Category

Calcium Carbonate Powder

Price 9 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Shape : Other, Granular powder

Chemical Composition : Calcium Carbonate (CaCO3)

Types of Refractories : Other, Nonrefractory

Strength : High compressive strength

Fullers Earth

Price 4 INR / Kilograms

Minimum Order Quantity : 1000 Kilograms

Shape : Powder or granular form, Other

Chemical Composition : Hydrated aluminum silicates

Types of Refractories : Other, Nonrefractory

Strength : Good compressive strength when compacted

Barite Powder

Shape : Other, Powder/Granular Form

Chemical Composition : BaSO4 (Barium Sulfate)

Types of Refractories : Other, NonRefractory

Strength : Excellent

China Clay

Shape : Other, Powder and blocks

Chemical Composition : Hydrated aluminosilicate (Al2Si2O5(OH)4)

Types of Refractories : Other, Nonrefractory

Strength : Good mechanical strength

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS